Unlocking Business Excellence: Empowering Organizations through Six Sigma School

We’re here to answer any question you may have.

Would you like to join our growing team?

info@sixsigmaschool.com

We’re here to answer any question you may have.

Would you like to join our growing team?

info@sixsigmaschool.com

A deep understanding of quality management principles and methodologies

Six Sigma Team are the core of every Lean Six Sigma implementation and are the real change agents in a Lean Six Sigma initiative. They will continually work toward institutionalizing the effective use of Lean Six Sigma tools throughout their organization. The program follows the DMAIC (Define, Measure, Analyze, Improve and Control) model and teaches the soft skills required to effectively lead projects.

The program consists of modules Designed mainly for Industry and Service all the Examples, Case Studies & Work Shops are built and will be deployed on Industry and Service

Each participant applies the training material through the completion of a project, and practical applications are reviewed throughout the program. Additionally, the application of Lean Six Sigma methodology.

Identifying Organizational and Strategic Goals.

Defining Customer Needs.

Collecting the Voice of the Customer.

Managing Organizational Processes and Their Measurements.

Influencing Stakeholders.

Critical to X Requirements (CTx).

Benchmarking.

Business Performance Metrics.

Financial Metrics.

Voice of the Customer

Identifying Customers.

Customer Feedback.

Customer Requirements.

Project Charter.

Project Charter.

Project Scope.

Objectives and Goals

• Project Performance Metrics.

• Project Tracking

• Applying SIPOC Process Map.

•Measurement System Analysis.

• GR&R

• AIAG

• BLA

• BA

• AA

• Applying the Composite Structure.

• Process Flow Diagram.

• High-Level Process Map.

•Priority Map.

• Value Stream Map.

•Logistics Map

•Production Flow Map.

• Process Characteristics.

• Input and Output Variables.

• Process Flow Metrics.

• Process Analysis Tools.

• Data Collection.

• Types of Data.

•Measurement Scales.

• Sampling Methods.

• Data Collection.

•Measurement Systems

•Measurement Methods

•Measurement Systems Analysis.

•Measurement Systems in an Organization.

•Measurements.

• Basic Statistics

• basic terms.

• Central Limit Theorem.

•Descriptive Statistics

• Graphical Methods.

• Correct Statistical Inferences.

• Process Capability Analysis.

• CPK

• PPK

• CPM

• PPM

• CP

• PP

• Graphical Analysis.

• Fishbone Diagram.

• Root Cause Analysis.

•The 5 Whys Technique.

•Symmetry Diagram.

• ID Diagram.

• Fault Tree.

• Power Matrix.

•Measurement and Modeling of Relationships Between Variables.

•Correlation Coefficient.

Program Designed to start from the First step of Six Sigma, Lean, Kaizen, Kaizen Blitz, Blitz & House of Quality and Gradually Increase Knowledge Dose to Achieve Maturity Level of Using Improvement Tools and its Deployment in Industry & Services

Program Designed to be

Topic | Model | Percentage |

Strategic Concept | Lecture | 5 % |

Integrated Quality Models | Lecture + Discussion | 5 % |

Infrastructure Creation | Lecture + Work Shop + Case Studies | 5 % |

Six Sigma Methodology | Lecture + Work Shop + Case Studies | 20 % |

Lean Applications in | Lecture + Work Shop + Case Studies | 20 % |

Kaizen , Kaizen Blitz , Blitz & House of Quality Applications | Lecture + Work Shop + Case Studies | 20 % |

Complete Improvement Projects | Work Shops + Case Studies + Similar Studies with Numbers | 25 % |

Looking for a corporate solution?

We are passionate about Business Excellence. We are a team of dedicated professionals with a deep understanding of quality management principles.

Our services including:

We are committed to upholding the highest standards of ethics, professionalism, and integrity in all our engagements. Our policy ensures transparency, confidentiality, and a client-centric approach to delivering exceptional results.

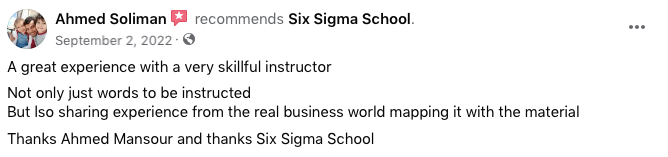

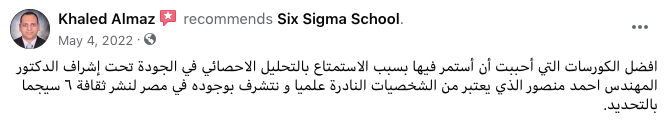

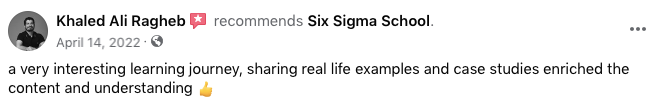

Our training model combines theoretical knowledge with practical application, ensuring that participants gain hands-on experience and skills that they can immediately apply in their work environment. We use interactive learning methods, case studies, and real-world scenarios to enhance the learning experience.

“Different Training plan for each company”

TRUSTED BY GLOBAL BRANDS

Adding {{itemName}} to cart

Added {{itemName}} to cart